From felt pens to digital tracking: Improving inventory controls in uranium production

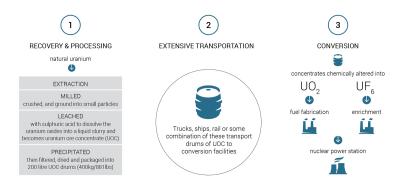

When natural uranium makes its way from rock to fuel conversion, it may travel through several countries with different legislation and practices. However, there is no global tracking system in place.

Industry is able to detect the loss or theft of a single drum of uranium ore concentrate (UOC), or yellowcake, within one to thirty days at mines, mills or during transport. Major producers employ in-company controls within their supply chains, and a number of states have national databases for nuclear materials, but not all UOC in a state may be captured in these databases.

- Drum filling and inventory management processes are automated at many facilities. Despite the automation, drums are labelled with felt markers and recorded in paper ledgers, although various electronic formats are more and more replacing the traditional ledgers. The fact that automated systems do not extend to drum labelling or barcoding seems counterintuitive in the digital age, particularly at newly built multimillion-dollar facilities, says Cindy Vestergaard, senior researcher at DIIS.

She is leading the Governing Uranium project, a global research effort studying the implications of a changing uranium market, specifically the production, processing and transport of UOC. In total, 15 uranium producing and consuming countries have been studied, and the results have been presented in a series of reports. The concluding report is published 28 August and points to demands for both industry best practices and harmonisation of regulation.

Digital tracking more important than ever

In the last few years, new uranium producers and consumers have entered a heavily regulated market, some of them without having their own regulation and best practice in place. At the same time, uranium can travel long distances, often across several borders, requiring multiple approvals in multiple jurisdictions.

- In Africa, for example, drums of UOC can travel in a private security convoy in one country while in another, the military shows up. At some ports, uranium has to be stored below deck, at others it has to be above deck. Harmonisation of transport would be a great first start, says Cindy Vestergaard.

These long distances and multiple jurisdictions makes digital tracking more important than ever according to Cindy Vestergaard.

The output from approximately 50 global uranium mines is delivered to only a handful of converters in Canada, China, France, Russia, and United States. This concentration of facilities greatly simplifies the task of tracking uranium and the provision of physical security.It also means that conversion facilities face the greatest struggles regarding inventory controls as they can amass large volumes in their storage lots. While the inventory of a shipment is reconciled by the shipper and receiver at the gates of the conversion facility, drums can be stored at conversion plants for years.

- The use of digital tracking systems would alleviate the backlog and inventory challenges at conversion plants to provide almost real-time tracking. Similarly, barcoding could provide greater control and inventory efficiencies at mines and mills. While barcoding systems that are currently in place at some facilities are used internally, if coordinated between producer and converter, a more efficient and robust global ‘mine to conversion’ tracking system could be employed, says Cindy Vestergaard.